Pallet Labeler XPU XPU

LABELING SOLUTIONS FOR PALLETS

simple identification – safe distribution

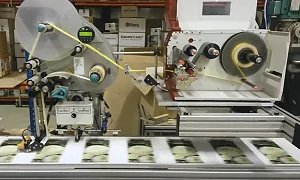

The XPU pallet labeler offers high levels of reliability, efficiency and user-friendliness, including demanding 24/7 applications, and delivers outstanding print results even in the rough conditions of a logistics environment.

- applies GS1 compliant DIN A5 labels

- labeling optionally 2 sides with just one pallet stop

- marking up to 180 pallets per hour

- fully readable barcode thanks to optional scanner

- options: scanner for barcode validation, RFID ability, 3 side labeling

Specificatie

PRODUCT HIGHLIGHTS

HIGH PRODUCTIVITY

- Reliable labeling of one or two adjacent pallet sides with just one pallet stop

- The pallet labeler XPU labels up to 180 pallets per hour at two labels per pallet

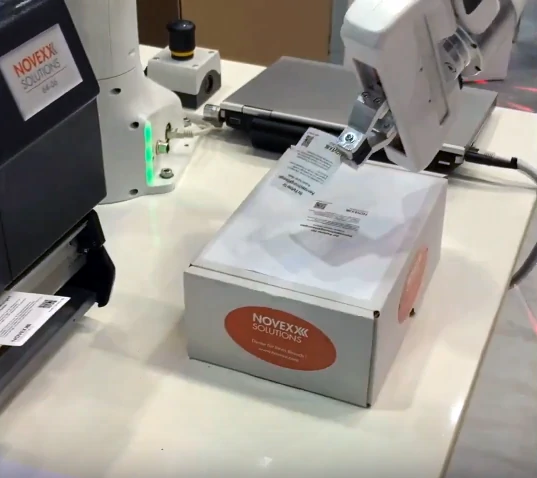

GS1 COMPLIANCE

- Print and apply GS1 compliant labels on different heights of your pallets

- The traceability of your pallets is guaranteed along the entire supply chain

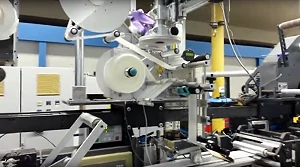

HIGHEST DEGREE OF RELIABILITY

- The XPU is based on the proven ALX 926 print and dispensing system

- Excellent print results at 300 dpi print resolution

- A home sensor protects the machine from damage due to moving pallets

ROBUST DESIGN

- The compact and sturdy design of the XPU means it can also withstand the rigors of particularly demanding environments

- A sturdy housing reliably protects the machine for example wie z.B. dust, dirt

HIGH FLEXIBILITY

- Best print results for scripts, logos, barcodes, variable or fixed data

- The XPU pallet labeler can be positioned on the left or right of the conveyer belt, as required

- The flexible telescopic applicator labels one or two sides, as desired, with just one pallet stop

SIMPLE HANDLING

- Easy data handling and straightforwaed control via ethernet

- A door at the front of the housing facilitates quick and simple changeover of label rolls and thermal transfer ribbon

- Easy access to the applicator arm and print and dispensing system enables even faster maintenance

« Lijst